围坝&填充胶

围坝&填充胶组合旨在为特定区域的元件进行保护。宝特威产品拥有高玻璃化温度和低膨胀系数,可以有效提升元件的可靠性水平。

围坝&填充胶组合提升元件对外部应力、如热应力的抵抗性。

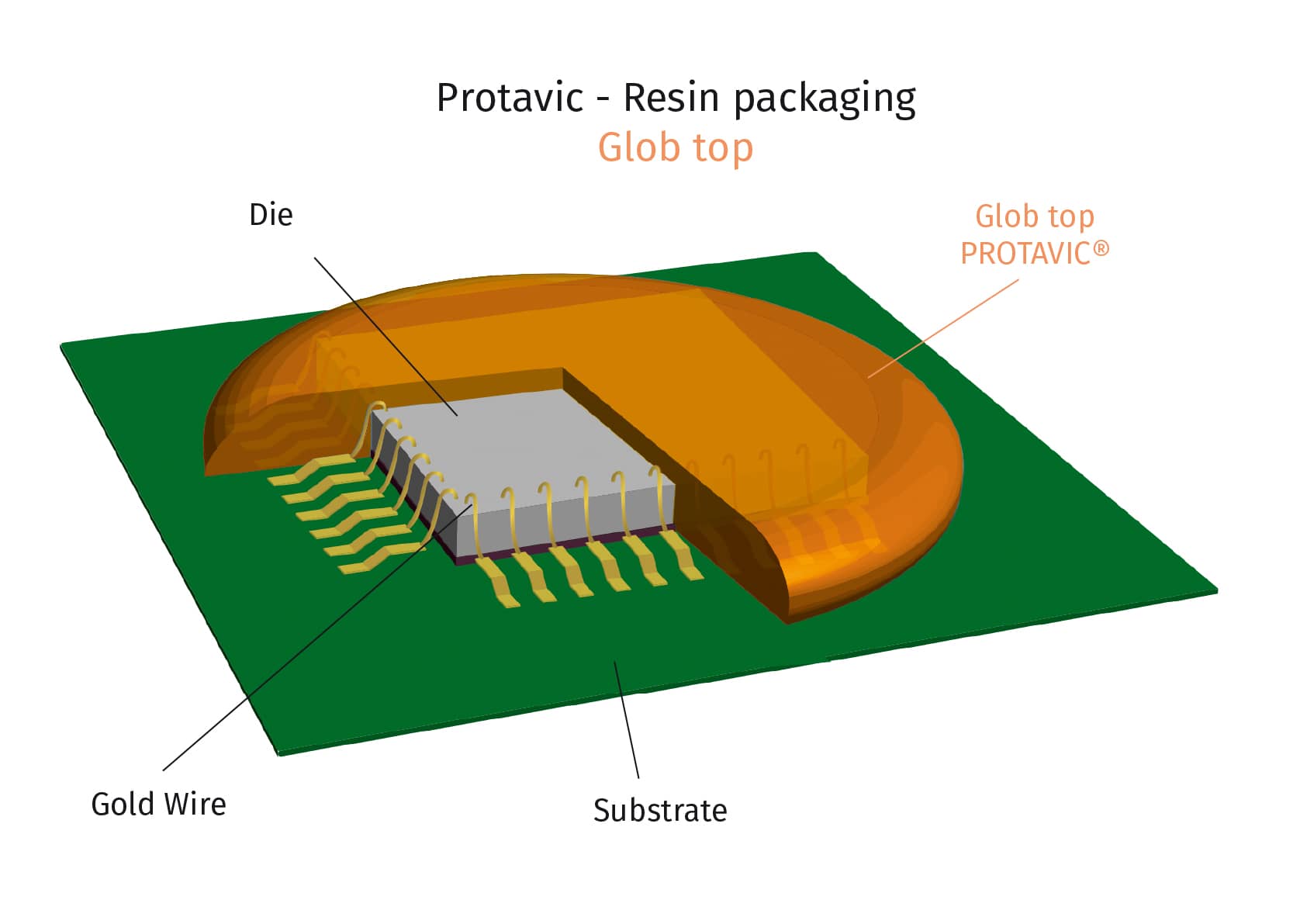

圆顶包封胶在小尺寸的芯片上可以实现相同的保护效果。

宝特威提供多样化的产品组合,全方位覆盖客户的产品需求。

系列产品如下图表中所示。

Technical description

Name/品名

Color/颜色

Chemistry/基系

Density/比重

Viscosity at 25°C (mPa.s)/粘度

TG/玻璃化温度

CTE(ppm/°C)/热膨胀系数

Shore hardness/硬度

Thermal conductivity (W/(m.K)/导热率

Use/用途

Dielectric strength (kV/mm)/介电强度

Open time/使用寿命

Polymerization/固化条件

Storage/储存寿命

Associated Fill product/关联产品

Thixotropic index of the Fill/触变

PROTAVIC® PNC 20120

Black

Cyanate ester

1.7

25000

210°C

25

D95

-

Dam

-

24 hours

30 min at 150°C + 4h at 200°C

6 months at -20°C

PROTAVIC® PNC 20014

1.3

PROTAVIC® PNE 30252

Black

Epoxy

1.76

105000

140°C

24

D90

-

Dam

-

24 hours

20 min at 150°C

3 months at -20°C

PROTAVIC® PNE 30270

-

PROTAVIC® PNE 30270

Black

Epoxy

1.7

70000

150°C

20

D85

0,7

Fill

>15

24 hours

35 min at 120°C + 1h at 150°C

6 months at -20°C

PROTAVIC® PNE 30252

-

PROTAVIC® PNE 90595

White

Epoxy

1.4

16000

24°C

160

D50

-

Dam

-

-

30 sec at 120 mW/cm² UV A

6 months at 5°C

PROTAVIC® PNE 90295

1.1

PROTAVIC® PNC 20120

Black

Cyanate ester

Chemistry/基系1.7

Density/比重25000

Viscosity at 25°C (mPa.s)/粘度210°C

TG/玻璃化温度25

CTE(ppm/°C)/热膨胀系数D95

Shore hardness/硬度-

Thermal conductivity (W/(m.K)/导热率Dam

Use/用途-

Dielectric strength (kV/mm)/介电强度24 hours

Open time/使用寿命30 min at 150°C + 4h at 200°C

Polymerization/固化条件6 months at -20°C

Storage/储存寿命PROTAVIC® PNC 20014

Associated Fill product/关联产品1.3

Thixotropic index of the Fill/触变PROTAVIC® PNE 30252

Black

Epoxy

Chemistry/基系1.76

Density/比重105000

Viscosity at 25°C (mPa.s)/粘度140°C

TG/玻璃化温度24

CTE(ppm/°C)/热膨胀系数D90

Shore hardness/硬度-

Thermal conductivity (W/(m.K)/导热率Dam

Use/用途-

Dielectric strength (kV/mm)/介电强度24 hours

Open time/使用寿命20 min at 150°C

Polymerization/固化条件3 months at -20°C

Storage/储存寿命PROTAVIC® PNE 30270

Associated Fill product/关联产品-

Thixotropic index of the Fill/触变PROTAVIC® PNE 30270

Black

Epoxy

Chemistry/基系1.7

Density/比重70000

Viscosity at 25°C (mPa.s)/粘度150°C

TG/玻璃化温度20

CTE(ppm/°C)/热膨胀系数D85

Shore hardness/硬度0,7

Thermal conductivity (W/(m.K)/导热率Fill

Use/用途>15

Dielectric strength (kV/mm)/介电强度24 hours

Open time/使用寿命35 min at 120°C + 1h at 150°C

Polymerization/固化条件6 months at -20°C

Storage/储存寿命PROTAVIC® PNE 30252

Associated Fill product/关联产品-

Thixotropic index of the Fill/触变PROTAVIC® PNE 90595

White

Epoxy

Chemistry/基系1.4

Density/比重16000

Viscosity at 25°C (mPa.s)/粘度24°C

TG/玻璃化温度160

CTE(ppm/°C)/热膨胀系数D50

Shore hardness/硬度-

Thermal conductivity (W/(m.K)/导热率Dam

Use/用途-

Dielectric strength (kV/mm)/介电强度-

Open time/使用寿命30 sec at 120 mW/cm² UV A

Polymerization/固化条件6 months at 5°C

Storage/储存寿命PROTAVIC® PNE 90295

Associated Fill product/关联产品1.1

Thixotropic index of the Fill/触变